Hemp Seed Hulling Machine

Hemp Seed Dehulling Machine

Our hemp seed hulling machine is expertly engineered to delicately remove the outer shell from hemp seeds with precision and efficiency.

Models For Sale: HDM150, HDM400

Utilizing advanced technology, it ensures a high degree of purity and integrity in the hulled seeds, minimizing waste and maximizing yield. The machine’s adjustable settings allow for customization according to seed size and condition, making it versatile for various batches.

Other Applications For Your Needs

Poly as a leading manufacturer of hulling and shelling machine, we produces all kinds to meet your various raw materials. Here are the raw materials we can deal, click to get the ideal machinery based on your needs.

Hemp Seed Hulling Machine For Sale

Our hemp seed dehulling machine features state-of-the-art design tailored for the effective separation of hemp seed shells from the nutritious cores.

In Poly, there are two major hemp seed processing equipment for sale, one is HDM150 series for small capacity, one is HDM400 series for large capacity.

Engineered for high-capacity processing, it can handle substantial volumes with a gentle touch, preserving the seeds’ integrity. The machine’s precision calibration tackles various seed sizes, ensuring a clean hull with minimal breakage.

Its robust stainless steel construction resists wear and corrosion, guaranteeing longevity. The integrated vacuum-powered debris collection system enhances the purity of the end product.

This machine is a turnkey solution for hemp producers aiming for top-tier market standards in seed preparation.

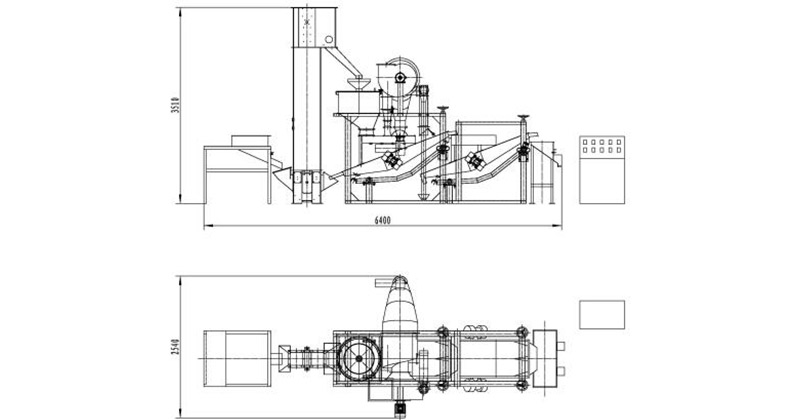

HDM150 Hemp Seed Hulling Machine

| Power | 4.7kW (380v) |

| Output | 150-200kg/h |

| % of Seeds in the Kernels | 2% Max. |

| % of Kernels in the Shells | 0.5% Max. |

| Occupied Area | 6.4m x 2.6m |

| Height | 3.51m |

| Weight | 1.5 ton |

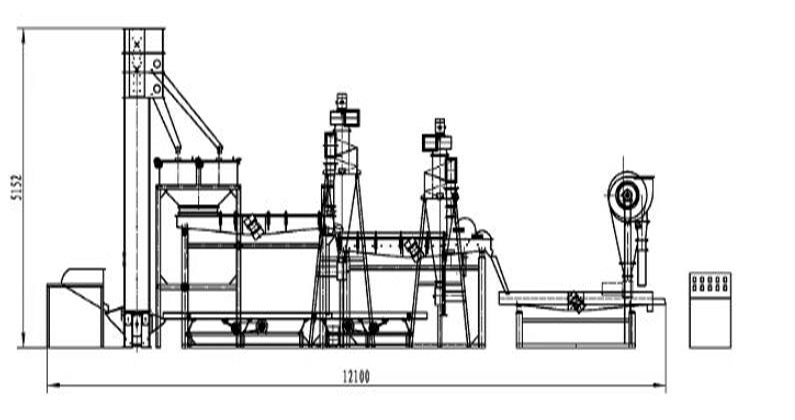

HDM400 Hemp Seed Hulling Machine

| HDM400 | HDM800 | TFHM150 | TFHM300 | |

| Power(KW) | 13.8 | 16.15 | 4.7 | 6.95 |

| Output (kg/h) | 400-500 | 800-1000 | 100-150 | 200-300 |

| % of Seeds in the Kernels | Below 0.2% | Below 0.2% | Below 0.5% | Below 0.5% |

| % of Kernels in the Shells | Below 0.2% | Below 0.2% | Below 0.5% | Below 0.5% |

| Dimensions (m) | 8.75×3.5×3.95 | 12.1x 6.0x 5.15 | 6.4 x 2.6 x 3.51 | 7.3×2.8×4.3 |

Applications of Hemp Seed Shelling Machine

The hemp seed shelling machine is a vital piece of equipment in the hemp industry, catering to the growing demand for hemp-based products. Its primary application lies in food production, where it prepares shelled hemp seeds, known for their nutritional benefits, to be used in health foods, snacks, and culinary ingredients. These seeds are rich in protein, omega fatty acids, and fiber, making them a sought-after component in the health food sector.

Additionally, the machine serves the agricultural industry by processing seeds for planting, ensuring high germination rates due to the intact, viable cores. The cosmetic industry also benefits, as the raw material obtained is used in creating hemp oil and beauty products.

Moreover, its use extends to pharmaceuticals, where hemp seeds are gaining recognition for their medicinal properties. The machine’s efficiency in preserving the seeds’ quality makes it indispensable for research and development in nutraceuticals, where precision and purity are paramount.

Key Components of Hemp Seed Dehuller

The key components of a hemp seed dehullers are designed to work in unison to efficiently separate the hull from the seed with minimal damage to the product. Here are the crucial parts:

- Feeding Mechanism: This component ensures a steady and controlled flow of hemp seeds into the machine for uniform hulling. It’s often equipped with a hopper and a conveyor system.

- Adjustment Gates: These gates control the volume of seeds entering the hulling chamber, which is vital for maintaining the efficiency of the hulling process.

- Hulling Unit: The core of the machine, where the actual dehulling takes place. It usually includes a set of rotating discs or blades that apply the necessary friction or impact to break away the hull without crushing the seed.

- Aspiration System: After hulling, this system removes the lighter hulls from the heavier seeds by using an air flow, ensuring separation.

- Vibratory Sieves: These sieves sort the seeds from the hulls based on size. They are often multi-layered to catch seeds and hulls of different sizes and to recirculate any un-hulled seeds back into the machine.

- Control Panel: This allows operators to adjust the settings of the hulling machine, such as speed and pressure, to cater to different seed batches and conditions.

- Discharge Outlets: Separate outlets for hulled seeds and hulls facilitate easy collection and further processing or disposal.

- Recirculation System: Not all seeds are hulled in the first pass. This system returns unprocessed seeds to the hulling chamber for reprocessing.

Each component is critical to the hulling process, and their quality and coordination determine the efficiency, yield, and quality of the final hulled hemp seeds.

Working Principle of Hemp Seed Shelling Machine

The hemp huller operates on the principle of controlled mechanical manipulation to effectively separate the outer shell from the inner seed, known as the hemp heart. Initially, the machine employs a feeding mechanism, typically a conveyor or a chute, to introduce hemp seeds into the shelling unit consistently and evenly.

Once inside, the machine utilizes a combination of sieves and shakers. The sieves are graded to the approximate size of the hemp seeds, allowing seeds to pass through while retaining the larger, unwanted debris. The shakers facilitate the movement of seeds against abrasive surfaces or between rotating rubber belts, applying just enough friction to crack the hard outer hulls without damaging the delicate inner seeds.

After the hulls are cracked, the machine takes advantage of the difference in size, shape, and weight between the hulls and the hemp hearts. Using a series of vibrating screens and air blowers, the lighter hull fragments are separated and removed, often with the aid of a vacuum system to ensure thorough cleaning.

The precision in the adjustment of the mechanical components is crucial, as it determines the effectiveness and efficiency of the hulling process. The end result is a clean separation of the hulls, leaving behind whole, undamaged hemp hearts ready for further processing or direct application in various industries. The shelling machine’s design often includes features for easy cleaning and maintenance, ensuring consistent performance and adherence to food-grade processing standards.

Features of Our Machine

Precision Control System

Our hulling machine features a state-of-the-art precision control system that allows for fine-tuning of hulling intensity, accommodating different seed sizes and conditions with ease.

Energy-Efficient Design

Engineered for sustainability, our machine boasts an energy-efficient design that reduces electricity consumption, lowering operational costs while maintaining high productivity.

Durable Construction

With high-grade stainless steel, our hulling machine withstands the rigors of continuous operation, ensuring longevity and reliability in high-volume processing environments.

Advanced Aspiration System

The machine includes an advanced aspiration system that effectively separates hulls from seeds, enhancing product purity while minimizing waste & creating a cleaner workspace.

The Total Cost of Ownership of Hemp Seed Hulling Equipment

Understanding the total cost of ownership (TCO) of hemp seed hulling equipment is crucial for producers aiming to make informed investment decisions. The initial purchase price of a hulling machine is just the tip of the iceberg. To gauge the true cost, buyers must consider several additional factors over the equipment’s lifespan.

Operational costs, including energy consumption and labor, are ongoing expenses that can accumulate significantly. Efficient machines that minimize energy use and automate processes can lead to substantial savings. Maintenance and repair costs also contribute to TCO. Regular servicing and the occasional replacement of parts are necessary to keep the machine running optimally, and a lack of maintenance can lead to costly downtime.

Moreover, the durability and longevity of the equipment play a pivotal role. A more affordable machine that requires frequent repairs or replacement can ultimately cost more than a pricier, but more reliable, option. Lastly, the resale value of the equipment should be considered. Quality machines with a reputation for longevity may retain more value and provide a return on investment upon resale.

In essence, the TCO of hemp seed hulling equipment encompasses purchase price, operational expenses, maintenance, durability, and potential resale value, painting a comprehensive picture of the investment’s economic impact.

How Efficient Hulling Can Minimize Product Loss

Efficient hulling is paramount in minimizing product loss in the processing of seeds, including hemp. Advanced hulling machinery is engineered to maximize the yield of intact seeds while reducing waste.

One key aspect of efficient hulling is the precision adjustment of machinery to accommodate different seed sizes and conditions. This adaptability ensures that the hulling process is gentle enough to prevent seed damage but forceful enough to remove the hulls effectively. By optimizing the hulling pressure, the incidence of cracked or crushed seeds is significantly reduced, preserving the quality and quantity of the final product.

The incorporation of real-time monitoring systems in hulling equipment is another innovation that contributes to efficiency. These systems can detect and adjust to variations in seed quality or moisture content, ensuring consistent processing and reducing the risk of over-hulling, which can lead to product loss.

Moreover, efficient hulling machinery often includes features such as recirculation systems that reintroduce unprocessed or partially processed seeds back into the hulling cycle. This feature ensures that every seed has the maximum chance of being hulled correctly, further reducing waste.

By leveraging these technological advancements, producers can achieve a higher rate of seed recovery, ensuring that as much product as possible is retained for sale or further processing, thus enhancing profitability and sustainability.

Customer’s Feedback

After years of use, Poly hulling machine has proven exceptionally durable and cost-effective. Its precise hulling capabilities have consistently delivered high-quality seeds with minimal maintenance required. Highly Recommended!

Indonesia / Jerry

About Poly Hulling Machine

Poly Hulling Machine stands as a premier provider of seed processing equipment, boasting over 25 years of industry expertise.

Our catalog features a diverse array of machinery, including hemp seed hulling lines, grain dehulling systems, seed cleaning machines, automated sorting units, advanced drying technology, and precision sifting equipment.

Poly Hulling Machine is dedicated to delivering pioneering solutions tailored to the unique requirements of our global clientele.

25+

Years Served

100+

Countries Exported

80+

Finished Projects

40+

Types of Machines

Talk to Our Expert For More About Poly Hulling Machinery Details.