Seeds Hulling Machine

25+ Years Experience in Dehuller Machine Innovation & Production

Buy Seeds Huller From Poly Machinery

Raw Materials that Can Deal With:

Hemp seeds / Sunflower seeds / Pumpkin seeds / Oat seeds / Buckwheat seeds / Almond / Sacha Inchi / Grain / Sesame / Walnut / Wheat / Soybean / Peanut / Cashew nut / Coconut / Groundnut / Hazelnut / Pistachio / …

Output Capacity:

300-1200kg/h

Usages:

– Small scale for home use.

– Middle scale for commercial use.

– Large scale for industrial use.

Types of Raw Materials We Can Deal

Our seed shelling machine is designed to handle a variety of raw materials, efficiently extracting the valuable kernels from an assortment of seeds and nuts.

Major Types of Dehulling Machine For Sale

Our lineup of dehulling euipment is meticulously engineered to cater to diverse agricultural and processing needs. We proudly offer five major types of hulling machines for sale, each specialized to handle the unique requirements of different seeds and grains with precision and care.

The Hemp Seeds Hulling Machine is tailored to delicately remove the outer shell of hemp seeds, ensuring the nutritious heart of the seed remains intact. For those dealing with the bright blooms of sunflowers, our Sunflower Seeds Dehulling Machine is optimized to gently separate the shells from the kernels, maximizing yield and purity.

Cereal enthusiasts can rely on our Oat Seeds Shelling Machine, which is designed to de-husk oats efficiently, preserving their natural goodness for a healthy breakfast staple. Our Pumpkin Seeds Deshelling Machine adeptly tackles the tough exterior of pumpkin seeds to reveal the pepitas, perfect for snack enthusiasts and culinary experts alike.

Lastly, the Buckwheat Huller stands ready to process this versatile grain, known for its use in a variety of health-conscious recipes, ensuring a clean and intact product ready for consumption or further processing.

Each machine in our range is built with durability, efficiency, and ease of use in mind, providing a seamless and productive hulling experience.

Hemp Seeds Shelling Machine For Sale

In Poly, there are two major hemp seed processing equipment for sale, one is HDM150 series for small capacity, one is HDM400 series for large capacity.

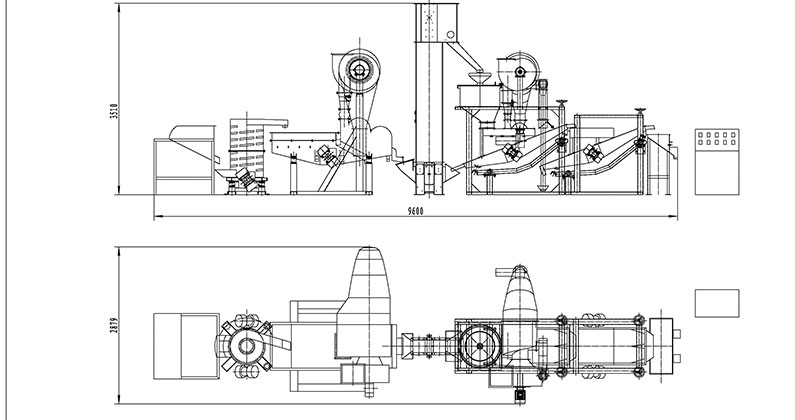

HDM150 Hemp Seed Hulling Machine

| Power | 4.7kW (380v) |

| Output | 150-200kg/h |

| % of Seeds in the Kernels | 2% Max. |

| % of Kernels in the Shells | 0.5% Max. |

| Occupied Area | 6.4m x 2.6m |

| Height | 3.51m |

| Weight | 1.5 ton |

HDM400 Hemp Seed Dehulling Machine

| HDM400 | HDM800 | TFHM150 | TFHM300 | |

| Power(KW) | 13.8 | 16.15 | 4.7 | 6.95 |

| Output (kg/h) | 400-500 | 800-1000 | 100-150 | 200-300 |

| % of Seeds in the Kernels | Below 0.2% | Below 0.2% | Below 0.5% | Below 0.5% |

| % of Kernels in the Shells | Below 0.2% | Below 0.2% | Below 0.5% | Below 0.5% |

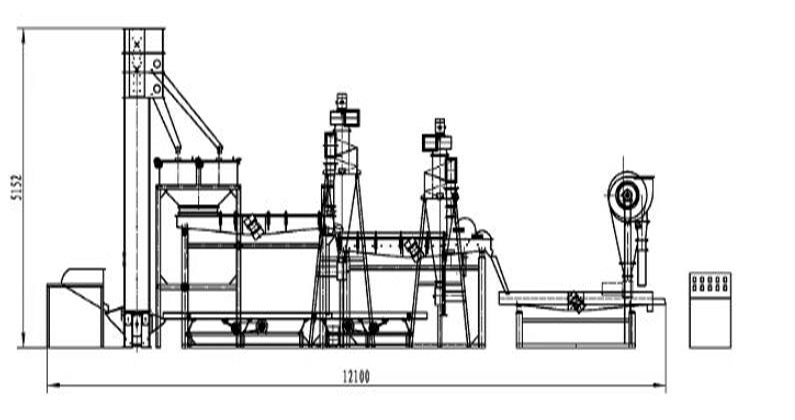

| Dimensions (m) | 8.75×3.5×3.95 | 12.1x 6.0x 5.15 | 6.4 x 2.6 x 3.51 | 7.3×2.8×4.3 |

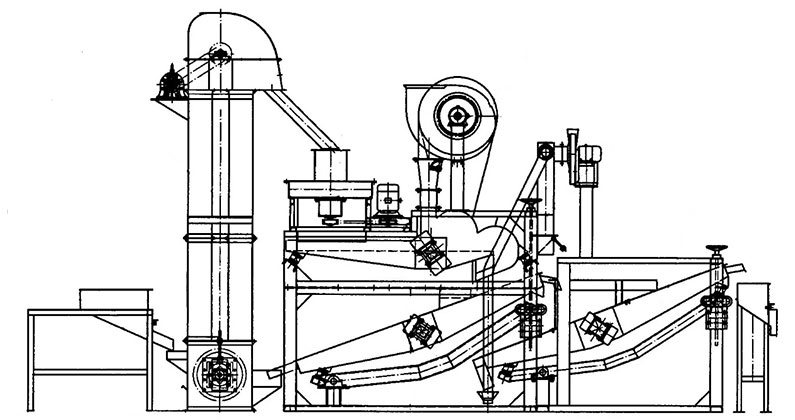

Key Components of Hemp Seeds Dehuller

A Hemp Seeds Dehuller is equipped with a feeding hopper for seed input, a dehulling assembly consisting of specially designed rollers or disks that crack the seed hulls, and a vibration screening system that sorts the hulled seeds from the shells.

An airflow separation unit is used to further clean the seeds by blowing away the lighter hull fragments. The machine’s operation is managed through a control panel, which allows for fine-tuning of dehulling parameters. Constructed with stainless steel, it ensures hygiene and longevity, while safety features like emergency stops and guards are incorporated to protect users during operation.

Sunflower Seeds Shelling Machine For Sale

In our company, we offer four types of sunflower seed hulling machines for sale: TFKH1500, YTK2000, TF600, and mini type. TFKH1500 is suitable for high-volume commercial use, YTK2000 for medium-scale production, TF600 for small factories or laboratories, and the mini type for individuals or small-scale growers.

TFKH1500 Sunflower Seed Dehulling Machine

| Power | 19.12kW (with cleaner) |

| Output | 700-1200kg/h |

| Whole Kernel | 90% Min. (Kernels that less than 1/2 whole kernels are broken) |

| De-hulling Rate | 95%-98% |

| Loss in the Shells | ≤0.3% |

| Occupied Area | 11.3m x 2.8m x 5.8m (vertical type) & 14.3m x 2.8m x 5.2m (horizontal type) |

| Weight | 6 ton |

YTK2000 Sunflower Seed DeHuller

| Power(KW) | 21.98kW (with cleaner) |

| Output (kg/h) | 1500-2000 |

| Whole Kernel | 90% Min. |

| De-hulling Rate | 97%-99% Min. |

| Loss in the Shells | ≤0.1% |

| Occupied Area | 12.1m x 2.8m (without cleaner) & 15.4m x 3.1m (with cleaner) |

| Height | 5.25m |

| Weight | 6.5T/7.2T |

TF600 Sunflower Seed Sheller

| Power(KW) | 4.65 |

| Output (kg/h) | 150-200 (depends on variety, sizes and moisture) |

| Whole Kernels | 90% Min. (broken kernel is less than 1/2 of whole kernel) |

| De-hulling Rate | 95%-99% |

| Occupied Area | 6.5m x 2.6m |

| Height | 3.3m |

| Weight | 1400kg |

Small Scale Sunflower Seed Dehuller

| Power(KW) | 2.35/2.65 |

| Output (kg/h) | 30-50 (single head) & 50-70 (double head) |

| Whole Kernels | 95% Min. |

| Weight | 350kg (single head) & 370kg (double head) |

| Dimensions (m) | 1750x1400x2500mm (single head) & 1750x1400x2700mm (double head) |

Key Components of Sunflower Seeds Dehuller

A Sunflower Seed Dehuller is characterized by a robust impact hulling unit, where seeds are cracked using a high-speed rotating impact ring. This component is crucial for breaking the tough outer hull without crushing the softer seed inside. The impact force is finely adjustable to cater to different cultivars of sunflower seeds. Following the hulling process, the machine incorporates a cascade of sieves which effectively sorts the kernels from the loosened hulls through vibratory grading. An integrated air-recycling aspirator then suctions off the lighter hull particles, enhancing the purity of the final product. The machine’s contact surfaces are often made of non-corrosive materials to prevent oxidation and ensure longevity.

Oat Shelling Machine For Sale

The TY1000 oat hulling machine is specifically engineered to de-hull, remove shells, and effectively separate oats. With its compact hullers controlled by a frequency converter, it offers precise speed adjustments to regulate capacity and minimize broken kernels.

TY1000 Oat Dehuller For Sale

| Power | 7.45kW |

| Output | 1000-1200kg/h |

| Whole Kernel | 95% Min. (Kernels that less than 1/2 whole kernels are broken) |

| Loss in the Shells | 0.3% Max. |

| Height | 3.75m |

| Occupied Area | 8m x 2.8m |

| Weight | 3 ton |

Key Components of Oat Dehuller

An Oat Huller is outfitted with a feed hopper for consistent grain delivery, a rotating dehulling disc or cylinder that abrades the hulls without damaging the groat, and an adjustable clearance setting to cater to different oat sizes. It incorporates a centrifugal separation system to segregate hulled oats from the loose hulls, and a sieve shaker for grading and additional separation. The air recycling system removes dust and lightweight hulls. Control is managed through a user-friendly interface, and the construction is of food-grade materials with safety interlocks and emergency stops to ensure operator safety and compliance with industry standards.

Pumpkin Seeds Shelling Machine For Sale

TFP150/300 Series Pumpkin Seed Hulling and Separating Machine is specifically tailored for the dehulling of pumpkin seeds, bottle gourd seeds, and other similar seeds from fruits.

TFP150/300 Pumpkin Seed Sheller

| Models | TFP150 | TFP150P | TFP300 | TFP300P |

| Power | 9.6kW | 10.36kW | 17.6kW | 18.7kW |

| Output | 150-200kg/h | 150-200kg/h | 300-400kg/h | 300-400kg/h |

| Whole Kernel | 98% Min. | 98% Min. | 98% Min. | 98% Min. |

| De-hulling Rate | 99.5% Min. | 99.5% Min. | 99.5% Min. | 99.5% Min. |

| Dimensions(mm) | 5400x1100x2750 | 6700x1100x3700 | 6500x1100x3200 | 6500x1100x3950 |

| Weight | 1200kg | 1550kg | 2400kg | 2720kg |

Key Components of Pumpkin Seeds Huller

A Pumpkin Seed Dehulling Machine is specifically designed with a vibratory feed mechanism to ensure a uniform flow of seeds into the dehulling unit. The hulling assembly typically features a series of rubber discs or blades that gently press and crack the hulls. The shelling gap is precisely adjustable to accommodate varying seed sizes and to optimize hull removal. Inside, a rotary drum or screw auger helps to transport and separate seeds from their hulls. A dual-screening system segregates the kernels from the debris, while an aspirator channels away the lighter hull fragments. Robust stainless steel construction ensures durability and compliance with food-grade standards.

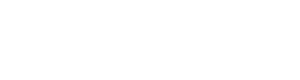

Buckwheat Hulling Machine For Sale

The TFQM400 buckwheat hulling and separating machine is known as one of the most effective buckwheat hullers worldwide. It efficiently hulls buckwheat while automatically separating the kernels from the husks and removing impurities.

TFQM400 Buckwheat Huller

| Power | 6.44kW |

| Output | 300kg/h |

| Whole Kernel | 98% Min. |

| % of Seeds in the Kernels | 0.5% Max. |

| % of Kernels in the Shells | 0.5% Max. |

Key Components of Buckwheat Seeds Dehuller

A Buckwheat Seed Shelling Machine is equipped with a precision metering device to deliver seeds consistently to the dehulling unit. The core dehulling mechanism often includes serrated discs or rollers that are specially designed to fracture the hard outer hulls without damaging the delicate inner kernels. An adjustable clearance setting allows the machine to adapt to different sizes and hardness of buckwheat seeds. Post-dehulling, the machine employs a centrifugal separation reel to efficiently separate the hulls from the kernels. A vibratory sieving unit further refines the separation process, ensuring that the end product is free of husks. The construction is typically of food-grade materials to prevent contamination.

What Other Materials We Can Deal With?

- Almond Shelling Machine: Our hulling machine is equipped with precision mechanisms to gently crack almonds’ hard shells, preserving the integrity of the edible kernel.

- Cashew Nut Shelling Machine: Our machine adeptly removes the tough outer layer of cashews, preparing them for the subsequent processing steps.

- Castor Seed Shelling Machine: Capable of dehulling the tough, spiky husks of castor seeds, our machine facilitates the safe extraction of the valuable seeds within.

- Coconut Deshelling Machine: Engineered to manage the fibrous husk of coconuts, our hulling machine efficiently separates the internal nut from its rugged exterior.

- Corn Shelling Machine: Our machine effectively strips the kernels from the cob, enhancing the efficiency of corn processing operations.

- Groundnut Shelling Machine: Tailored for groundnuts, our hulling machine efficiently removes the pods and husks, delivering clean, ready-to-process kernels.

- Melon Seed Shelling Machine: Our dehuller excels at separating the delicate melon seeds from their hulls, ensuring a high yield of clean seeds.

- Palm Kernel Shelling Machine: The hulling machine is capable of processing tough palm kernels, effectively separating the kernel from the fibrous husk.

- Peanut Shelling Machine: Our huller is specially designed to handle peanuts, ensuring the shells are removed without harming the edible seeds.

- Pistachio Sheller Machine: Our hulling machine carefully opens pistachios without damaging the nut, maintaining the quality and flavor.

- Soybean Sheller Machine: Optimized for soybeans, our machine efficiently removes the hulls to facilitate oil extraction and further processing.

- Walnut Shelling Machine: The hulling machine is fine-tuned to deal with walnuts’ hard shells, delivering clean kernels ready for consumption or processing.

- Wheat Sheller Machine: Our machine skillfully removes the outer bran layer from wheat kernels, preparing them for milling and other uses.

Dehuller Machine Price

The huller machine price can vary widely based on several factors, including its capacity, automation level, materials used in construction, manufacturer, and additional features such as sorting or cleaning capabilities. For example, a small-scale dehuller suitable for a local food processing facility might cost anywhere from $2,00 to $1,000, while a larger, industrial-grade machine with higher automation and throughput could range from $5,000 to $10,000 or more.

Entry-level dehullers, often with manual or semi-automatic features, are typically priced at the lower end of the spectrum. These are suitable for small businesses or startups that require lower production outputs. Mid-range models, which offer greater capacity and automation for consistent shelling and throughput, can be expected to fall in the middle price range. They often include features like variable size adjustments and may come with some form of digital control panel.

For large-scale operations that need fully automated systems with the highest efficiency, integrated cleaning systems, and the ability to handle multiple types of seeds or nuts, the investment is significant. Premium models could also include advanced features like real-time monitoring, remote control capabilities, and self-cleaning mechanisms.

It’s important to note that these prices are approximate and can change based on the supplier, current market conditions, and geographic location. Additionally, operational costs, such as maintenance and parts replacement, should also be considered when purchasing a dehuller machine.

Using Our Seeds Huller For Industrial and Commercial Use

Our de huller machine is an indispensable asset for industrial and commercial operations seeking to streamline their processing of nuts, seeds, and grains. Designed for heavy-duty use, it can withstand the rigorous demands of a continuous, high-volume production environment, ensuring that businesses can operate around the clock without sacrificing efficiency or quality.

The versatility of our dehuller makes it suitable for a wide range of applications. Whether it’s hulling almonds for confectionery, shelling peanuts for oil extraction, or preparing soybeans for tofu production, the machine’s adjustable settings allow for precise customization to the specific requirements of each material, ensuring optimal results.

Incorporating our seed huller into your production line can significantly reduce labor costs. It automates a process that is traditionally labor-intensive, freeing up your workforce for more skilled tasks and reducing the potential for human error. This automation also contributes to a safer workplace by minimizing the physical interaction workers have with the hard shells and mechanical components.

Furthermore, the machine’s state-of-the-art design ensures minimal maintenance downtime and is built to last, making it a cost-effective solution for businesses looking to invest in long-term operational efficiency. With the capacity to handle large quantities quickly and reliably, our huller machine is a smart choice for any commercial or industrial operation looking to boost productivity and profitability.

Low Cost Option: Small

Scale Dehuller For Small Business

Mini Sunflower Seed Hulling Machine

| Power(KW) | 2.35/2.65 |

| Output (kg/h) | 30-50 (single head) & 50-70 (double head) |

| Whole Kernels | 95% Min. |

| Weight | 350kg (single head) & 370kg (double head) |

| Dimensions (m) | 1750x1400x2500mm (single head) & 1750x1400x2700mm (double head) |

This is a mini sunflower seeds huller machine, if you intend to hulling other types of raw materials, we also have other small scale dehullers designed for specific seeds. Just contact us and tell us your requirements, we will recommend the most suitable types for you.

Features of Our Machine

High Efficiency Extraction

Our oil press machines are engineered for maximum oil yield with minimal waste, ensuring efficient extraction and superior throughput for various seeds and nuts.

Advanced Temperature Control

Equipped with precise temperature regulation, our machines maintain optimal heat levels to preserve the oil’s flavor and nutritional value during extraction.

Robust Construction

Constructed with high-grade materials, our oil press machines offer durability and longevity, reducing maintenance needs and ensuring continuous operation in demanding environments.

User-Friendly Interface

Designed with an intuitive interface, our machines allow for easy operation and monitoring, making the oil pressing process straightforward and accessible to operators of all skill levels.

Why Choose Automatic Shelling Machine?

Choosing an automatic shelling machine offers numerous benefits that significantly enhance processing efficiency and product quality. Firstly, automation ensures consistent performance, with the machine maintaining uniform hulling quality that manual labor cannot match. This consistency is crucial for meeting industry standards and achieving customer satisfaction.

Secondly, an automatic sheller machine dramatically increases throughput. It processes large volumes of nuts or seeds in a fraction of the time it would take human workers, thereby boosting productivity and enabling businesses to handle larger orders and scale operations.

Moreover, these machines are designed for precision. They can be finely adjusted to accommodate different sizes and hardness of shells, reducing the risk of damaging the valuable kernels inside. This precision leads to higher yields of intact, marketable product and less waste.

Worker safety is another significant advantage. Shelling nuts and seeds can be laborious and potentially hazardous due to hard shells and sharp edges. Automatic machines minimize the need for human handling, reducing the risk of repetitive strain injuries and other workplace accidents.

Lastly, in the long term, investing in an automatic shelling machine can be cost-effective. Despite the initial capital outlay, the reduction in labor costs and the increase in productivity can lead to substantial financial savings, making it a smart choice for businesses looking to optimize their operations.

Customer’s Feedback

After years of use, Poly hulling machine has proven exceptionally durable and cost-effective. Its precise hulling capabilities have consistently delivered high-quality seeds with minimal maintenance required. Highly Recommended!

Indonesia / Jerry

About Poly Hulling Machine

Poly Hulling Machine stands as a premier provider of seed processing equipment, boasting over 25 years of industry expertise.

Our catalog features a diverse array of machinery, including hemp seed hulling lines, grain dehulling systems, seed cleaning machines, automated sorting units, advanced drying technology, and precision sifting equipment.

Poly Hulling Machine is dedicated to delivering pioneering solutions tailored to the unique requirements of our global clientele.

25+

Years Served

100+

Countries Exported

80+

Finished Projects

40+

Types of Machines

Talk to Our Expert For More About Poly Hulling Machinery Details.