Sunflower Seed Hulling Machine

Sunflower Seed Dehulling Machine

Our sunflower seed hulling machine utilizes cutting-edge technology to efficiently remove hulls, boosting overall production efficiency.

Models For Sale: TFKH1500, YTK2000, TF600, Mini Type

It offers user-friendly operation, cost-effectiveness, and is specifically designed for large-scale production, making it an optimal choice for enhancing productivity and streamlining the hulling process in sunflower seed processing operations.

Other Applications For Your Needs

Poly as a leading manufacturer of hulling and shelling machine, we produces all kinds to meet your various raw materials. Here are the raw materials we can deal, click to get the ideal machinery based on your needs.

Sunflower Seed Hulling Machine For Sale

In our company, we offer four types of sunflower seed hulling machines for sale: TFKH1500, YTK2000, TF600, and mini type.

Each model is uniquely designed to cater to varying capacity and dehulling requirements.

TFKH1500 is suitable for high-volume commercial use, YTK2000 for medium-scale production, TF600 for small factories or laboratories, and the mini type for individuals or small-scale growers.

Whether you have high capacity or specific dehulling needs, our range of models caters to diverse requirements, providing efficient hulling solutions to enhance productivity and cost-effectiveness in sunflower seed processing operations.

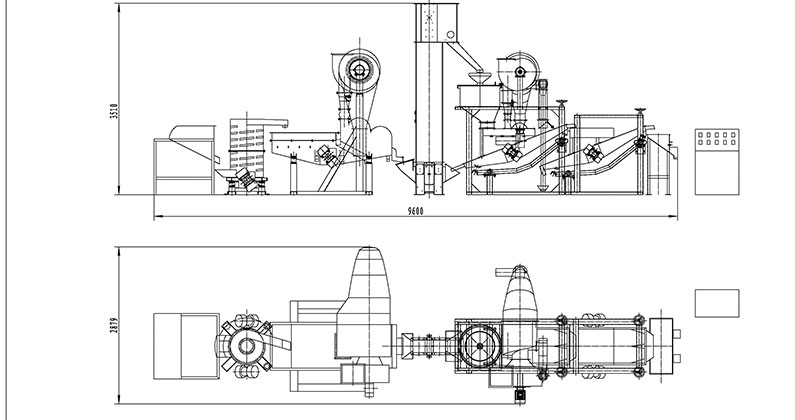

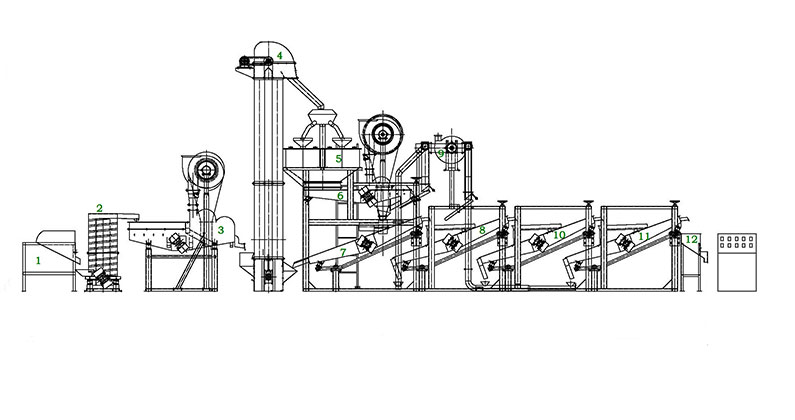

TFKH1500 Sunflower Seed Hulling Machine

| Power | 19.12kW (with cleaner) |

| Output | 700-1200kg/h |

| Whole Kernel | 90% Min. (Kernels that less than 1/2 whole kernels are broken) |

| De-hulling Rate | 95%-98% |

| Loss in the Shells | ≤0.3% |

| Occupied Area | 11.3m x 2.8m x 5.8m (vertical type) & 14.3m x 2.8m x 5.2m (horizontal type) |

| Weight | 6 ton |

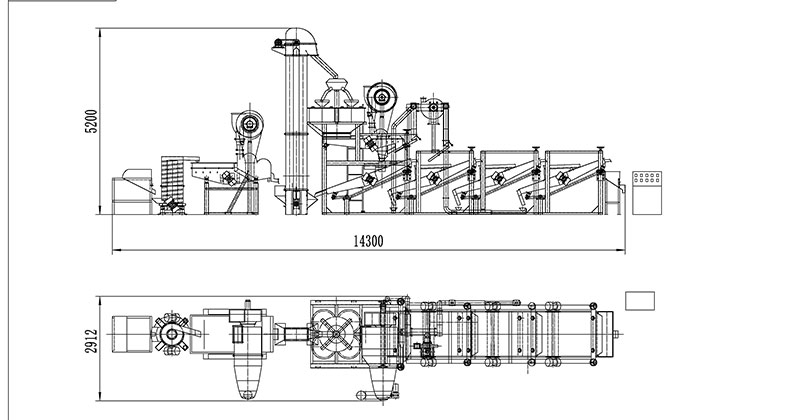

YTK2000 Sunflower Seed Hulling Machine

| Power(KW) | 21.98kW (with cleaner) |

| Output (kg/h) | 1500-2000 |

| Whole Kernel | 90% Min. |

| De-hulling Rate | 97%-99% Min. |

| Loss in the Shells | ≤0.1% |

| Occupied Area | 12.1m x 2.8m (without cleaner) & 15.4m x 3.1m (with cleaner) |

| Height | 5.25m |

| Weight | 6.5T/7.2T |

TF600 Sunflower Seed Hulling Machine

| Power(KW) | 4.65 |

| Output (kg/h) | 150-200 (depends on variety, sizes and moisture) |

| Whole Kernels | 90% Min. (broken kernel is less than 1/2 of whole kernel) |

| De-hulling Rate | 95%-99% |

| Occupied Area | 6.5m x 2.6m |

| Height | 3.3m |

| Weight | 1400kg |

Mini Sunflower Seed Hulling Machine

| Power(KW) | 2.35/2.65 |

| Output (kg/h) | 30-50 (single head) & 50-70 (double head) |

| Whole Kernels | 95% Min. |

| Weight | 350kg (single head) & 370kg (double head) |

| Dimensions (m) | 1750x1400x2500mm (single head) & 1750x1400x2700mm (double head) |

Applications of Sunflower Seed Shelling Machine

The sunflower seed shelling machine plays a pivotal role in various industries, offering a range of applications to meet the needs of sunflower seed processing. One of its primary applications is in the food industry, where sunflower seeds are shelled and processed for confectionery snack food. The machine efficiently removes the hulls, preparing the seeds for consumption or further processing.

Moreover, the oil extraction industry benefits from this equipment, as sunflower plants can be processed for oil extraction. The machine facilitates the dehulling and separation of the seeds for oil extraction, ensuring an efficient and seamless process. Sunflower seed oil extracted from this process is valued for its light color, rich unsaturated fatty acids, and suitability for cooking, making it an essential part of the edible oil industry.

Additionally, sunflower seed processing plants utilize the machine to prepare non-oil seeds, which are used in confectionery products and as ingredients in various food products. The machine ensures that the seeds are uniformly dehulled, graded, and roasted, meeting the quality standards required for food-grade seeds. This versatility in processing non-oil seeds caters to the diverse needs of the food industry, contributing to the creation of various food products.

Furthermore, the sunflower seed shelling machine finds application in the production of animal feed and industrial uses. Sunflower plants can be processed for animal feed, manure, fertilizer, and other industrial purposes, with the machine playing a crucial role in dehulling and seed processing for these applications. The high-quality dehulled seeds and the by-products of extraction contribute to the production of quality feed and industrial materials, adding value to the agricultural and industrial sectors.

In conclusion, the applications of the sunflower seed shelling machine are diverse, spanning industries such as food processing, oil extraction, animal feed production, and industrial use. Its ability to efficiently dehull, peel, and sort sunflower seeds makes it an indispensable tool in meeting the diverse processing needs across these industries, contributing to the overall efficiency and quality of sunflower seed processing.

Key Components of Sunflower Seed Hulling Machine

The sunflower seed hulling machine comprises several key components that collectively contribute to its efficient operation in dehulling and processing sunflower seeds. One essential component is the feeding mechanism, which is responsible for the uniform and continuous feeding of sunflower seeds into the hulling chamber. The feeding mechanism ensures a steady input of seeds, optimizing the hulling process.

Another critical component is the hulling chamber, where the actual dehulling of sunflower seeds takes place. This chamber is equipped with specially designed rollers or blades that effectively remove the hulls from the seeds, ensuring thorough dehulling while minimizing damage to the kernels. The design and configuration of the hulling chamber play a crucial role in determining the efficiency and effectiveness of the dehulling process.

The separation and classification system is another vital component of the sunflower seed hulling machine. This system facilitates the separation of hulls, kernels, and other impurities after the dehulling process. It ensures that the dehulled seeds are properly sorted and classified, leading to high-quality output and reducing the presence of unwanted impurities or unprocessed seeds in the final product.

Furthermore, the machine’s control and monitoring system, including sensors, actuators, and a user interface, are integral components that enable operators to monitor and regulate the machine’s operation. This system provides real-time feedback on parameters such as seed flow, hulling efficiency, and overall machine performance, allowing for adjustments and optimization as needed.

In addition to these key components, the sunflower seed hulling machine may also incorporate cleaning mechanisms, aspiration systems, and safety features to enhance its overall functionality and user safety.

Overall, the synergy of these key components ensures the sunflower seed hulling machine’s ability to efficiently and effectively dehull sunflower seeds, providing quality output while optimizing the processing operations. Their robust design and integration contribute to the machine’s performance and its critical role in sunflower seed processing operations.

Working Principle of Sunflower Seed Shelling Machine

The working principle of a sunflower seed shelling machine involves a systematic process aimed at efficiently dehulling sunflower seeds. Upon entering the machine, sunflower seeds are uniformly and continuously fed into the hulling chamber, which houses a rotor or blades designed for dehulling. As the seeds move through the hulling chamber, they undergo the action of the rotor or blades, resulting in the separation of the hulls from the seeds. This process is carried out with precision to ensure the thorough removal of the outer hulls while preserving the integrity of the kernels.

Subsequently, the dehulled seeds are then separated from the hulls and any remaining impurities through a sorting and screening mechanism. This step ensures that the dehulled seeds are properly cleaned and classified, leading to high-quality output. The working principle emphasizes uniform feeding, efficient dehulling, and thorough separation to deliver optimal results.

By adhering to this working principle, the sunflower seed shelling machine is able to achieve high efficiency and accuracy in dehulling operations, making it an indispensable tool for the sunflower seed processing industry. This systematic approach ensures the production of dehulled sunflower seeds that meet quality standards, contributing to the overall efficiency and productivity of sunflower seed processing operations.

Features of Our Machine

Precision Control System

Our hulling machine features a state-of-the-art precision control system that allows for fine-tuning of hulling intensity, accommodating different seed sizes and conditions with ease.

Energy-Efficient Design

Engineered for sustainability, our machine boasts an energy-efficient design that reduces electricity consumption, lowering operational costs while maintaining high productivity.

Durable Construction

With high-grade stainless steel, our hulling machine withstands the rigors of continuous operation, ensuring longevity and reliability in high-volume processing environments.

Advanced Aspiration System

The machine includes an advanced aspiration system that effectively separates hulls from seeds, enhancing product purity while minimizing waste & creating a cleaner workspace.

The Total Cost of Ownership of Sunflower Seed Hulling Equipment

The Total Cost of Ownership (TCO) of sunflower seed hulling equipment encompasses the complete evaluation of all expenses associated with owning and operating the machinery throughout its lifecycle. In addition to the initial purchase cost, the TCO factors in maintenance, repairs, energy consumption, labor, training, downtime, and any potential resale or residual value of the equipment. This comprehensive assessment provides a more accurate representation of the actual cost of utilizing the equipment over time.

Calculating the TCO of sunflower seed hulling equipment aids businesses in making informed decisions regarding procurement, budgeting, and operational planning. By considering both the direct and indirect costs associated with the equipment, companies can better forecast expenses, optimize operational efficiency, and strategically allocate resources. Understanding the TCO enables businesses to evaluate the long-term financial implications of investing in sunflower seed hulling equipment, leading to more effective financial management and operational decision-making.

By comprehensively analyzing the TCO of sunflower seed hulling equipment, companies can make informed choices that align with their financial goals, operational needs, and overall business sustainability. This holistic approach to cost assessment assists in maximizing efficiency, reducing unforeseen expenses, and ensuring the equipment’s long-term value and productivity.

How Efficient Hulling Can Minimize Product Loss

Efficient hulling is paramount in minimizing product loss in the processing of seeds, including hemp. Advanced hulling machinery is engineered to maximize the yield of intact seeds while reducing waste.

One key aspect of efficient hulling is the precision adjustment of machinery to accommodate different seed sizes and conditions. This adaptability ensures that the hulling process is gentle enough to prevent seed damage but forceful enough to remove the hulls effectively. By optimizing the hulling pressure, the incidence of cracked or crushed seeds is significantly reduced, preserving the quality and quantity of the final product.

The incorporation of real-time monitoring systems in hulling equipment is another innovation that contributes to efficiency. These systems can detect and adjust to variations in seed quality or moisture content, ensuring consistent processing and reducing the risk of over-hulling, which can lead to product loss.

Moreover, efficient hulling machinery often includes features such as recirculation systems that reintroduce unprocessed or partially processed seeds back into the hulling cycle. This feature ensures that every seed has the maximum chance of being hulled correctly, further reducing waste.

By leveraging these technological advancements, producers can achieve a higher rate of seed recovery, ensuring that as much product as possible is retained for sale or further processing, thus enhancing profitability and sustainability.

Customer’s Feedback

Sunflower hulling machine exceeded expectations! Durable and cost-effective, it consistently delivers top-quality seeds with minimal upkeep. Highly recommended for efficient hulling operations.

Kenya / Parvel

About Poly Hulling Machine

Poly Hulling Machine stands as a premier provider of seed processing equipment, boasting over 25 years of industry expertise.

Our catalog features a diverse array of machinery, including hemp seed hulling lines, grain dehulling systems, seed cleaning machines, automated sorting units, advanced drying technology, and precision sifting equipment.

Poly Hulling Machine is dedicated to delivering pioneering solutions tailored to the unique requirements of our global clientele.

25+

Years Served

100+

Countries Exported

80+

Finished Projects

40+

Types of Machines

Talk to Our Expert For More About Poly Hulling Machinery Details.